欢迎进入山东恒能环保能源设备有限公司

欢迎进入山东恒能环保能源设备有限公司

沼气制取天然气(也称为生物甲烷或可再生天然气)的过程涉及将原始沼气提纯,以去除其中的二氧化碳、硫化氢等杂质,使其达到与传统天然气相似的质量标准。这一过程需要一系列设备和技术的支持。下面是一些关键设备和技术介绍:

The process of producing natural gas (also known as biomethane or renewable natural gas) from biogas involves purifying the raw biogas to remove impurities such as carbon dioxide and hydrogen sulfide, making it meet quality standards similar to traditional natural gas. This process requires a series of equipment and technical support. Here are some key equipment and technology introductions:

1. 沼气收集系统

1. Biogas collection system

厌氧消化池:这是产生沼气的地方,通过微生物在无氧条件下分解有机物来生成沼气。

Anaerobic digester: This is a place where biogas is produced by microorganisms decomposing organic matter under anaerobic conditions to produce biogas.

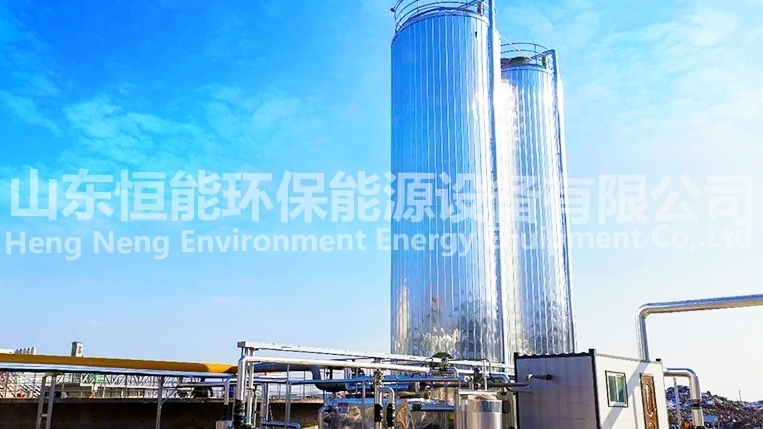

气体储罐:用于临时储存从厌氧消化池中收集到的沼气。

Gas storage tank: used for temporary storage of biogas collected from anaerobic digesters.

2. 预处理装置

2. Preprocessing device

脱硫装置:去除沼气中的硫化氢,因为高浓度的H2S对后续处理设备有腐蚀作用,并且不符合最终产品的质量要求。

Desulfurization device: removes hydrogen sulfide from biogas, as high concentrations of H2S have a corrosive effect on subsequent treatment equipment and do not meet the quality requirements of the final product.

水洗塔/冷却器:用来降低沼气温度并去除其中携带的水分,有助于提高后续净化效率。

Water washing tower/cooler: used to reduce the temperature of biogas and remove the water carried in it, which helps to improve the subsequent purification efficiency.

3. 净化分离技术

3. Purification and Separation Technology

膜分离技术:利用特殊材料制成的膜,在压力差的作用下实现CH4和CO2之间的选择性透过,从而达到分离的目的。

Membrane separation technology: using membranes made of special materials to achieve selective permeation between CH4 and CO2 under pressure difference, thus achieving the purpose of separation.

变压吸附(PSA):基于不同气体组分在固体吸附剂上的吸附能力差异,在周期性改变操作条件的情况下完成气体分离。

Pressure swing adsorption (PSA): Based on the differences in adsorption capacity of different gas components on solid adsorbents, gas separation is completed under periodic changes in operating conditions.

化学吸收法:使用特定溶液吸收沼气中的CO2,然后通过加热等方式释放CO2,使溶液可以循环使用。

Chemical absorption method: using a specific solution to absorb CO2 from biogas, and then releasing CO2 through heating or other methods, so that the solution can be recycled.

低温蒸馏:通过控制温度使得沼气中的主要成分按沸点高低顺序分离出来。

Low temperature distillation: By controlling the temperature, the main components in biogas are separated in order of boiling point.

4. 压缩与储存

4. Compression and Storage

压缩机:经过净化后的生物甲烷通常会被加压至高压状态,以便于运输或长期存储。

Compressor: Purified biomethane is usually pressurized to high pressure for transportation or long-term storage.

高压储罐:为确保安全有效地储存压缩后的生物甲烷而设计的专业容器。

High pressure storage tank: a specialized container designed to ensure safe and effective storage of compressed biomethane.

5. 监测控制系统

5. Monitoring and control system

包括但不限于气体分析仪、流量计、压力传感器等,用以实时监控整个生产流程中的各项参数,保证系统的稳定运行。

Including but not limited to gas analyzers, flow meters, pressure sensors, etc., used to monitor various parameters in the entire production process in real time, ensuring the stable operation of the system.

6. 安全防护设施

6. Safety protection facilities

由于涉及到易燃易爆气体的操作,因此必须配备相应的消防器材、泄漏检测报警系统以及紧急切断装置等安全保障措施。

Due to the operation involving flammable and explosive gases, corresponding fire-fighting equipment, leak detection and alarm systems, and emergency shut-off devices must be equipped with safety measures.

综上所述,从沼气转化为天然气是一个复杂但可行的过程,它不仅能够有效利用废弃物资源,还能减少温室气体排放,促进可持续发展。随着技术的进步和成本的下降,预计未来会有越来越多的项目采用这种方法来生产清洁燃料。不过值得注意的是,具体实施方案还需根据实际情况(如原料特性、地理位置等因素)进行调整优化。此外,虽然这里列出了一些常见设备,但在实际应用中可能还会涉及到更多细节方面的考虑。

In summary, the conversion of biogas to natural gas is a complex but feasible process that not only effectively utilizes waste resources, but also reduces greenhouse gas emissions and promotes sustainable development. With the advancement of technology and the decrease in costs, it is expected that more and more projects will adopt this method to produce clean fuels in the future. However, it is worth noting that the specific implementation plan still needs to be adjusted and optimized according to the actual situation (such as raw material characteristics, geographical location, etc.). In addition, although some common devices are listed here, there may be more detailed considerations involved in practical applications.

相关新闻